Thursday, 11 April 2013

A Visit to Phillips Mushroom Farm

Back in February the New Jersey Mycological Association held a mycophagy, mushroom eating, event. We watched as a chef prepared, discussed, and presented a diversity of dishes incorporating exotic mushrooms from Phillips Mushroom Farm. Which we then got to sample. Afterwards I thought about this and decided nothing ventured, nothing gained. I asked if I might visit and photograph at their facility in Kennett Square, Pennsylvania. The general manager, Jim Angelucci, graciously agreed and said he'd give me a tour. Some discussion and scheduling issues resolved, and on Thursday off I went for the lengthy ride across the river, skirting Philadelphia, passing Longwood Gardens without time for a visit - and there we were. We, because Joan, my agreeable and frequent travelling companion, was also along on this outing.

Why Kennett Square, Pennsylvania as mushroom capitol of the nation? It's a story that began over a hundred years ago. William Swayne grew carnations on elevated benches in his greenhouse in Kennett Square. There was all this waste space directly under those elevated beds. Importing mushroom spawn from Europe, Swayne began cultivating mushrooms in the space under the beds by hanging burlap curtains to create an environment of stable temperature and humidity in which his mushrooms could - more or less when compared to today - thrive. By 1924 the Pennsylvania Department of Agriculture reported that 85% of mushrooms cultivated in the United States were grown in Pennsylvania. And in 1930 the U.S. Census Bureau revealed that 350 of the 516 mushroom growers in the United States were in Chester County, Pennsylvania. From a minor sideline among area carnation growers, today mushrooms are the number one, multi-million dollar cash crop in the state.

Joan and I signed in. We had to show picture identification, remove our jewelry, wear a hair net and a visitor's badge.

Jim gave us a fantastic tour, driving us from building to building and tossing off a constant stream of facts and figures.

There's that old joke that goes something like "I must be a mushroom because they keep me in the dark and feed me bullshit." That's not right. The mushroom growing chambers are lit, though not excessively bright. Heat is an issue. And it is straw-bedded horse manure that the best substrate, compare to cow or pig manure. But that's not all. Aged hardwood sawdust, cottonseed hulls and / or cottonseed meal, millet grain bran, mulched straw, and soybean meal are incorporated. Different mushrooms demand specifically formulated growing medium and growing conditions of temperature, humidity, and carbon dioxide levels. Several times Jim mentioned their energy bills. The company had looked into solar energy but it just wasn't cost effective. They are green, in that all spent mushroom compost is recycled, popular with gardeners to improve the soil. Water is collected in lagoons and restored to the local hydrology.

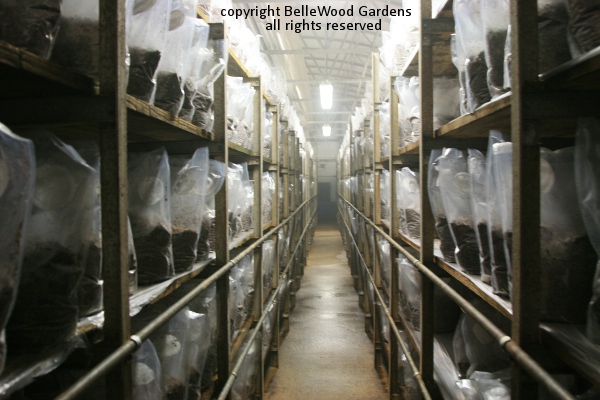

Within the long windowless concrete block buildings are rows of wooden beds, stacked several layers high, that extend for the length of the building. For Agaricus, the familiar white button mushroom, each growing cycle begins by cleaning out the old material. The beds are steam treated to pasturize them. The fresh growing compost that fills the beds is again steam treated before it is innoculated with the mushroom spawn, then lightly watered. When the mycellium have grown through the substrate a layer of peat moss is added to cover the compost, and it is watered again.

The web-like threads of the mushroom mycellium spreads through the compost.

The first mushrooms to appear are called "pins," for their tiny size. Mushrooms double in size in 24 hours. A bed in full production will be harvested multiple times a day. There are usually three flushes of growth, with decreasing yields for the second and third flushes. A cycle is 33 to 45 days, depending on the kind of mushroom. These baby bella or cremini are also Agaricus, just a different color form. All portobello are cremini but not all cremini are portobello. What's the difference? Once the veil on the underside of the mushroom cap tears the cap stops growing. If this happens while the cap is small the harvested mushroom is a cremini. When it grows to that yummy-for-grilling palm-size version, it's a portobello.

The cycle goes like this: first stage is composting for 6 to 14 days. Second stage involves the pasturization / heat sterilization for about 2 hours. Spawning and growth is the third stage, and takes 14 to 21 days at 75° to 80° degrees Fahrenheit. Any cooler, and growth is slowed, and hotter and the mycelia can be damaged. When the mycelium has propagated and grown through the whole compost layer at about 13 to 20 days a cap of peat moss is added. Pinning (the earliest formation of what we recognize as mushrooms) occurs at 18 to 21 days. Harvesting is repeated over 7 to 10 day cycles, and after three flushes the process begins all over again.

Not all mushrooms are grown in beds. Exotics, such as these shiitakes, are cultivated on artificial logs.

When grown on natural logs shiitake require the bark to remain or they won't grow. In cultivation these units

must form an artificial "bark" to replicate nature. Soaked in water tanks, drained, innoculated, grown.

This is a growing chamber for maitake mushrooms. Jim says they are fickle and difficult to grow.

The growing compost of hardwood sawdust, millet grain and bran partially fills each medical device bag

which is then sealed. The mycellium fills the bag. As the mushrooms begin to form one is selected and

the bag is slit at that point to allow it to grow to maturity. Maitake prefer high humidity,

as you may deduce from the water droplets forming on the immature mushroom.

Maitake have a 45 day growing cycle. "One of the tastiest mushrooms." in Jim's opinion.

Temperature, moisture, and humidity in the growing chambers are carefully monitored and regulated.

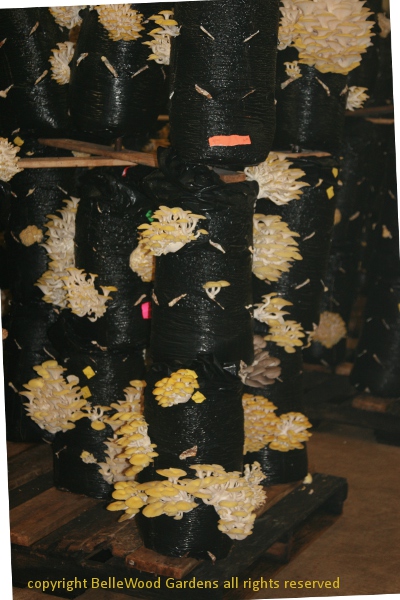

Oyster mushrooms, for example, require high humidity and low carbon dioxide. They prefer

cotton seed hulls in their substrate. The mycelium fill the plastic-wrapped cylinder which

is then slit, and the oyster mushrooms blossom forth. These yellow oyster mushrooms

have a 12 week grow cycle, are absolutely beautiful (and delicious!)

Gray oyster mushrooms.

Jim opened a shipping box of gray oyster mushrooms so I could peer inside.

A truck backed up to the loading dock, being filled with boxes of oyster mushrooms.

William Phillips started his mushroom business in 1927. Three generations and 86 years later the company sells mushrooms from Maine to Miami, just about everywhere east of the Mississippi River, selling over 35 million pounds of specialty mushrooms per year, more than any other mushroom farm in the United States. Mushroom growing is a labor intensive operation. All aspects of production, from composting, to spawning, and harvesting, involve manual labor. Mushrooms must be harvested and sorted by hand. Phillips Mushroom Farm has 450 permanent workers and additional contract labor. Most are Hispanic. Our tour today was also labor intensive. Jim generously shared of his time and expertise. My something ventured request was a tremendous gain of information all about mushrooms, with an inside look at how they're grown.